MACTEX Key Services

A Legacy of Leadership in Pneumatic Conveying Engineering

Our core competency in dry solid material handling, providing complete engineering solutions and comprehensive post-sale support for managing a diverse range of raw materials in dry powder and granular forms.

Engineered with meticulous attention to detail, the MACTEX powder handling system consistently delivers high-quality performance and reliability, meeting stakeholders’ expectation with precision.

MACTEX EPCC

From initial engineering and design to procurement of top-quality materials, followed by precise construction and thorough commissioning, our EPCC process guarantees optimal performance and client satisfaction at every stage.

Engineering

1

Understanding URS

MACTEX meticulously evaluates your User Requirement Specifications to tailor a perfect pneumatic conveying solution.

2

Feasibility Design (Site Visit)

Our experts perform detailed process flow requirements to ensure the proposed system integrates seamlessly with your application.

3

Preliminary Conceptual Design

We develop initial designs with a focus on optimizing cost, efficiency, and safety, aiming to exceed industry standards.

4

Submission & Discussion

We present and refine the preliminary design with you to ensure it aligns with your business objectives and technical requirements.

5

Technical Design Finalises

The final technical design is a comprehensive blueprint, ready for implementation after rigorous refinement based on your feedback.

Procurement

1

Project Management

Our project managers ensure that procurement aligns perfectly with project timelines and quality standards.

2

Sourcing and Vendor Selection

To uphold the reliability and quality standards of our product, we conduct rigorous consultation with meticulously selected and esteemed vendors.

3

Delivery Schedule Update

Regular updates on delivery schedules maintain transparency and help manage any potential delays.

4

Equipment QA, QC & FAT

Each piece of equipment undergoes stringent testing for quality assurance, control, and factory acceptance.

5

Deliver on schedule

We ensure all equipment and materials are delivered on time to commence construction without delay.

Construction

1

MOB / DEMOB (Mobilisation)

Mobilisation marks the beginning of the construction phase, setting up necessary infrastructure for installation.

2

Site Preparation and Erection

We meticulously prepare the site and erect structures while ensuring all safety protocols are followed.

3

Installation of Mechanical and Electrical

Our installation experts install all mechanical and electrical components and system setup, adhering to the highest standards with the supervision of qualified engineers.

4

Inspection

Continuous inspections during construction ensure the installation meets all expectations.

5

System QC Test

A comprehensive quality control test verifies the system’s operational efficiency before going live.

Commisioning

1

Functional Testing

We conduct functional testing to ensure each component meets operational specifications.

2

System Testing & Commissioning

Extensive testing ensures the system operates seamlessly and integrates perfectly with your operations.

3

Production Monitoring & Fine Tuning

We monitor the system post-commissioning to optimize operations and performance.

4

Training & Documentation

Extensive training and documentation are provided to ensure efficient operation and maintenance of the system.

5

System Performance Warranty & After Sales Service

MACTEX offers a comprehensive warranty and dedicated after-sales service to support and maintain your system.

Discover the MACTEX Advantage

Experience the MACTEX advantage with our unparalleled expertise in solid bulk material handling. Trust MACTEX for reliable systems that deliver exceptional performance, backed by comprehensive after-sales services.

Time and Cost Optimization

Quality Certification

Warranty Prolongation

Inventory Verification

Post-Sales Support

Rapid Response Rate

World Class Service at MACTEX

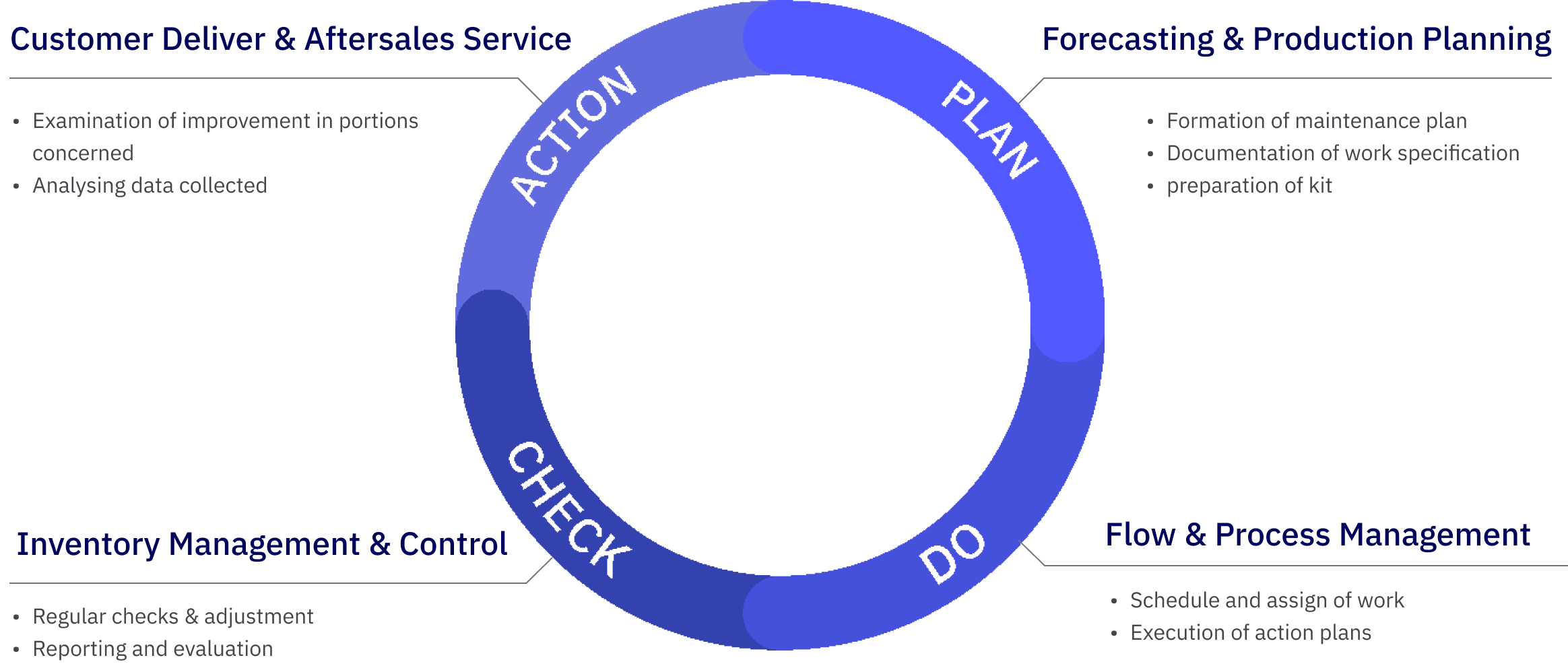

ACTION

Customer Deliver & Aftersales Service

- Examination of improvement in portions concerned

- Analyzing data Collected

PLAN

Forecasting & Production Planning

- Formation of maintenance plan

- Documentation of work specification

- preparation of kit

DO

Flow & Process Management

- Schedule and assign of work

- Execution of action plans

CHECK

Inventory Management & Control

- Regular checks & adjustment

- Reporting and evaluation